Our specialized areas

Our proven track record in critical technologies such as ultra-high vacuum, radiation environments, high magnetic fields, and cryogenics—along with turnkey project delivery aligned with stringent quality and regulatory standards—positions us as a strategic partner in the development and deployment of nuclear fusion systems.

Where

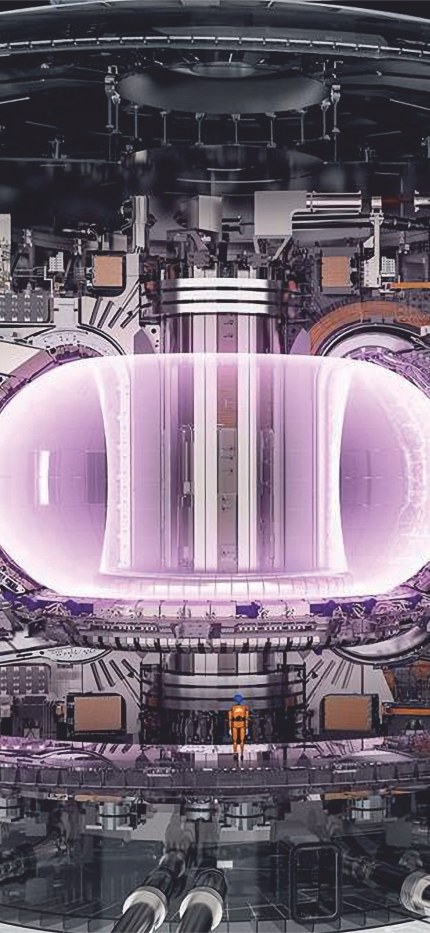

Tokamak fusion is a method of nuclear fusion where plasma is confined in a toroidal-shaped vessel using strong magnetic fields. The goal is to fuse light nuclei, like hydrogen isotopes, to release energy, replicating the process that powers the sun, with the potential for clean and sustainable energy.

A stellarator is a nuclear fusion device that uses complex magnetic coils to contain hot plasma and achieve fusion. Unlike tokamaks, it doesn’t rely on plasma current, offering potential for greater stability in fusion energy production.

Inertial fusion is a type of nuclear fusion in which fuel pellets, typically made of deuterium and tritium, are rapidly compressed by intense energy from lasers or other energy sources. The compression creates extremely high pressure and temperature, causing the nuclei to fuse and release energy.

How

Neutralizes the ions and safely dumps the electrons coming from the ion source, this beamline component is the first step in generating the neutral beam responsible of the NBI plasma heating.

Captures and dumps the residual ions of the neutralized beam, preventing them to impact and damage the reactor’s vacuum vessel. This beamline component is the second step in shaping up the neutral beam responsible of the NBI plasma heating.

Stop the neutral beam when injection into the vessel is not needed and characterizes the neutral beam during commissioning or pulse conditioning. This beamline is the last NBI component prior beam injection into drift duct’s/vacuum vessel.

Measures and maps the 3 components of the magnetic field in vessel, essential to provide feedback to operators to set magnetic coils and current drive to properly run and maintain plasma confinement.

Measures steady state local magnetic fields (tangential and normal components) and installed on the vacuum vessel outer shell as a poloidal array, those sensors will contribute to measurement of plasma current, plasma-wall clearance and local perturbations of the magnetic flux surfaces near the wall.

Large containment structures that house the plasma and associated systems, such as heating and diagnostic tools, and are typically placed at the core of the fusion reactor to maintain the vacuum and plasma confinement.

Use of robotic systems and automation to perform maintenance, repairs and inspections inside the fusion reactor, where high temperatures, radiation, and magnetic fields make it unsafe for humans. Remote handling is essential for managing the challenging environment of fusion reactors, particularly in long-term operations, and plays a key role in maintaining reactor performance and safety.

In fusion research, diagnostics are essential tools used to monitor plasma behavior and reactor conditions, providing real-time data on temperature, density and magnetic fields. Techniques like spectroscopy, neutron diagnostics and imaging systems help analyze plasma composition, fusion reactions and plasma stability, while divertor diagnostics assess material performance. These tools are crucial for optimizing fusion reactions and advancing sustainable energy production.

Pellet injectors as advanced fueling systems in fusion reactors that shoot small, frozen pellets of deuterium or deuterium-tritium into the plasma. They allow deeper fuel penetration than gas injection, improving plasma density control and fusion efficiency. Pellet injection is also used to help manage instabilities and is key for steady-state operation in devices like tokamaks and ITER.

Trusted by

Global leaders in fusion technology— including the reference project ITER—trust our capabilities. Our expertise in large-scale scientific infrastructure, multidisciplinary engineering, and turnkey execution under strict quality standards positions us as a strategic partner in advancing next-generation fusion systems.