THALES THALES Monochromator shielding, Guide changer, Velocity selector stage

2014 | ILL

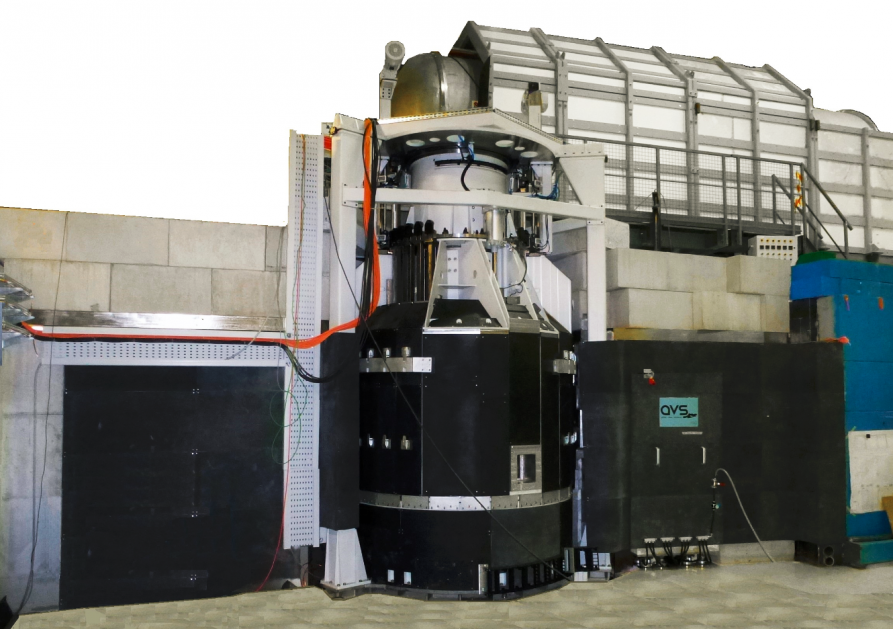

AVS was in charge for the turnkey design, construction and on-site installation of the Monochromator shielding, Casemate shielding and all the optics of the Thales instrument, delivered at ILL.

CASEMATE

The casemate shielding contains the optical elements up-stream placed inside the incident white neutron beam. The optical elements are (in the neutron flight path direction from the source to the monochromator): guide sections mounted on a vertical two-stage lifting system, the velocity selector mounted on a translation stage and a sapphire single crystals filter. It includes the diaphragm ‘Virtual source’ with horizontal variable aperture and the primary shutter OS1. It guarantees the biological shielding according to ILL radio-safety standards as well as a neutron and gamma background level as low or lower than the present IN14 spectrometer inside the experimental zone. It provides access from the ThALES experimental zone from the top for maintenance work and removal of the optical elements up-stream. It also guarantees access to the motor A2 inside the monochromator shielding. The casemate shielding guarantees high field experiments (15T on sample position) for all possible positions of the ThALES sample table.

MONOCHROMATOR

The monochromator shielding contains the mononchromator stage. It assures the biological shielding according to ILL radio-safety standards as well as a neutron and gamma background level as low or lower than the present IN14 spectrometer inside the experimental zone. The upper stage of the shielding is rotating around the central A1/A2 axis. During the rotation shielding blocks are lifted to avoid collision with the guides H51 and H52 under the condition that no direct view from the experimental zone to the monochromator position is possible. The inner diameter of the shielding must be sufficiently large for hosting the monochromator stage and has to assure its correct positioning. It has to assure the rotation of the sample table around the collinear rotation axes A1 and A2. It has to assure the access to the monochromator stage and the guides H51 and H52 for maintenance work.

OPTICS

The selector moves horizontally of 135 mm with an accuracy of 0.1mm. The time to change position is less than 30s. Sensors are placed at each extremity to manage the movement. There is a system of hand-regulating and clamping. The system can be adjusted laterally (10mm), horizontally (5°), and on height (10mm). The whole changer speed selector and his translation must be easily removable. The output is done by the door of the casemate (with chocking) provide connectivity interfaces motor/sensors. The cage includes the OS and Diaphragm. There is a lateral setting (10mm), horizontally (5°), and height (10mm).

Client: ILL